TIREMAAX ROI Calculator

TIREMAAX ROI Calculator

Calculate the Return on Investment for your fleet by installing TIREMAAX PRO Tire Inflation System on your trailers.

TIREMAAX Whitepaper

TIREMAAX Whitepaper

With a focus on increased productivity, fleets are constantly looking for ways to reduce costs and increase up-time.

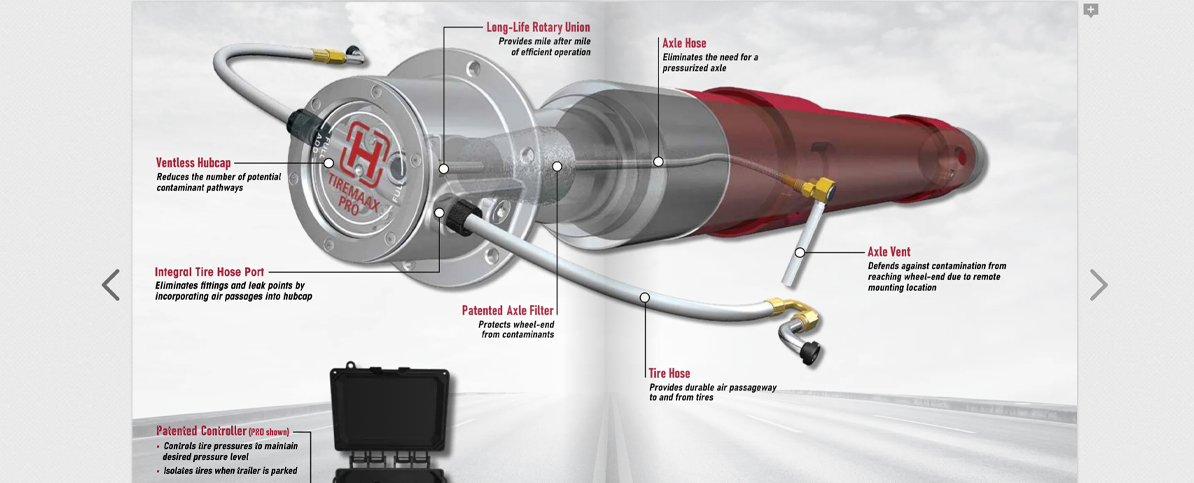

TIREMAAX Digital Catalog

TIREMAAX Digital Catalog

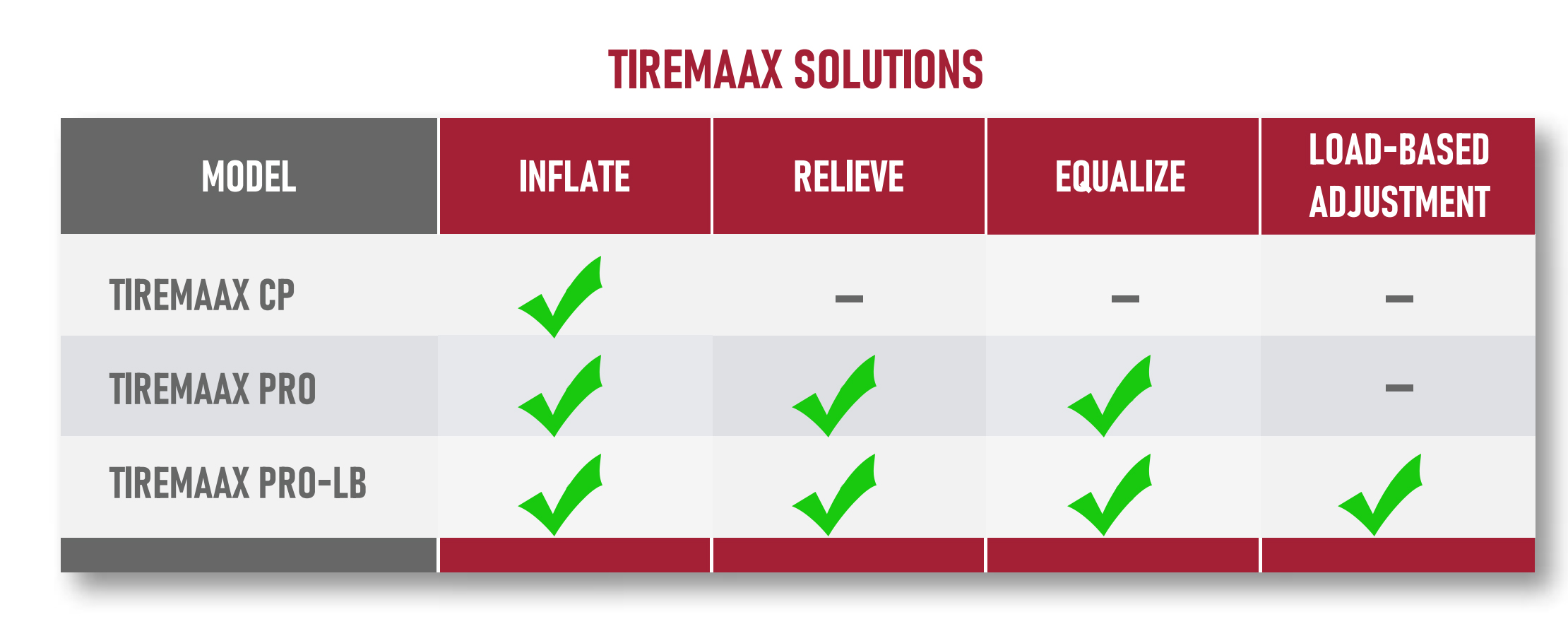

TIREMAAX is an important feature for achieving maximum tread life in any trailer tire configuration.