SUSTAINABLE LOW CO2 FOOTPRINT

Hendrickson composite springs offer many unique benefits over steel suspension systems. Among them is weight reduction for improved range, improved ride and comfort and corrosion and sag resistance.Composites are manufactured with a very low carbon footprint versus comparable steel springs.

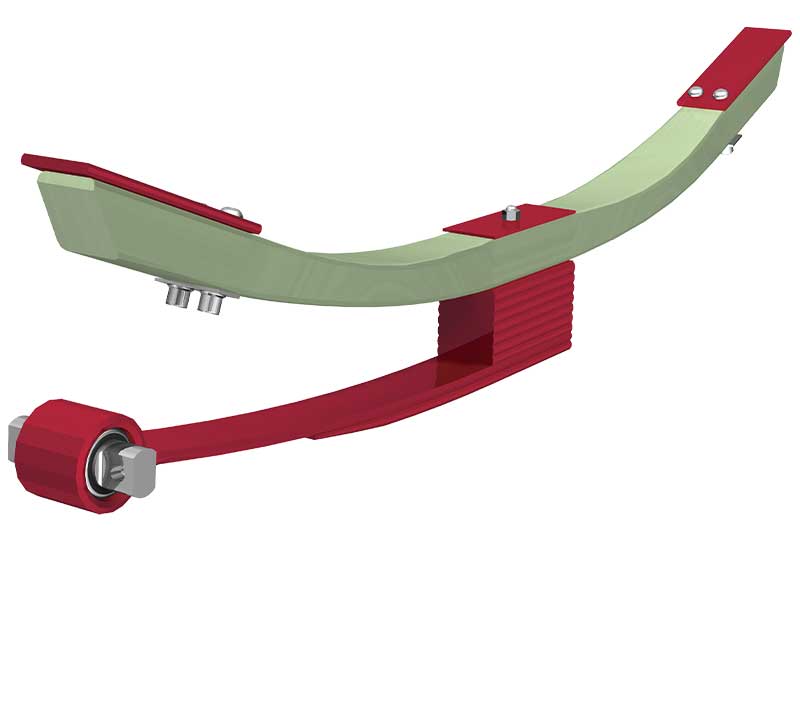

Hybrid Spring

Technology

Combine steel and composite springs to gain the benefits of eye bushing connections and lightweight, corrosion resistant, long-lasting composites.

LONG-TERM PERFORMANCE

We have measureable results against steel spring competitors.Sustainability

Filament winding manufacturing technology offers a sustainable low CO2 footprint.

Sag Resistance

Composite springs have a proven track record of not sagging over time compared with steel springs.

Durability

Testing results show composite springs resist corrosion and last longer than steel springs.

Weight Savings

Hendrickson heavy-duty composite springs are up to 50 percent lighter than traditional class-8 springs.

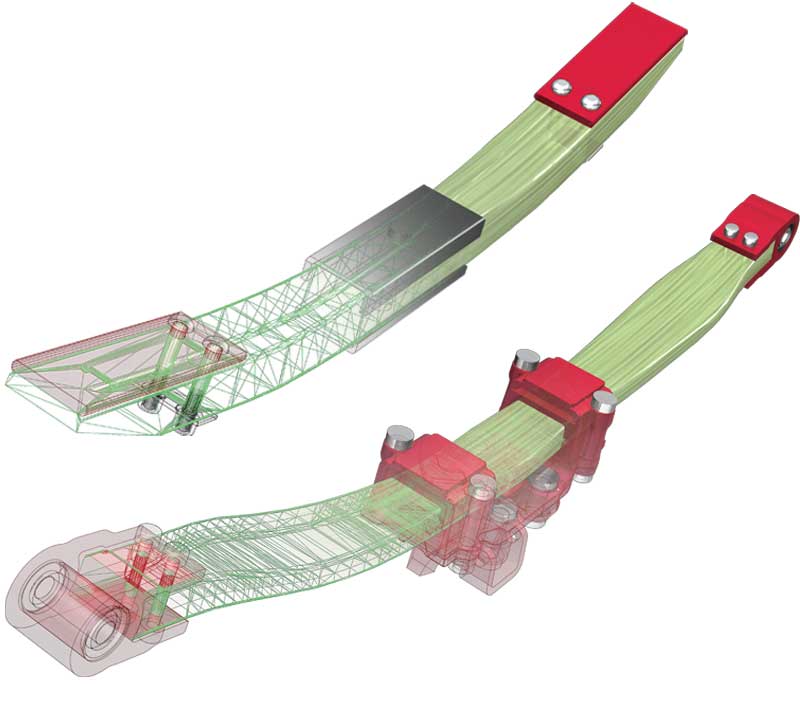

Lightweight

Durable Technology

Hendrickson heavy-duty composite springs are up to 50 percent lighter

than traditional class-8 springs. Composites help improve fuel efficiency

and payload capacity without sacrificing durability. They are corrosion

and sag resistant, maintain ride height and provide improved vibration

and harshness feedback. Hendrickson composite springs are a proven

option for vehicle OEMs and owners around the globe.

COMPOSITE SOLUTION SOURCE

Hendrickson composite springs offer vehicle OEMs better packaging with systems that require less space, allowing for lower hood lines, elimination of coil towers and help with lowering drag coefficients. Smaller spring requirements also allow for larger interior space and / or more passenger amenities without increasing overall vehicle weight.