Sales and Marketing Questions

1. How is TIREMAAX® PRO different from TIREMAAX CP Integrated?

To date, all tire inflation systems (TIS) only react to a decrease in tire pressure. TIREMAAX PRO reacts to both decreases and increases in tire pressure as indicated by the examples in the table:

| Condition |

Gauge

Pressure1

|

TIREMAAX

CP |

TIREMAAX

PRO |

| Slow leak |

↓ |

✓ |

✓ |

| Pressure change due to drop in tire temperature |

↓ |

✓ |

✓ |

| Pressure change due to increase in tire temperature |

↑ |

|

✓ |

| Increased elevation |

↑ |

|

✓ |

| Decreased elevation |

↓ |

✓ |

✓ |

| Status indicator lamp ON during inflation |

↓ |

✓ |

✓ |

| Equalizes tire pressures for a balanced system. |

↕ |

|

✓ |

1. The value displayed on a gauge relative to the current atmosphere.

2. Why do I need relief control?

A tire is designed to operate at a specific pressure, as specified by the tire manufacturer, for maximum performance and minimum tire wear. Running with under or over inflated tires will not only affect performance on the road, but will decrease the life of the tire.

Refer to question 1.

3. Since TIREMAAX PRO can relieve tire pressure, what safeguards are in place to keep tires from losing pressure if the system has a malfunction? The current TIREMAAX CP has check valves in each tire hose to keep a flat tire from draining an inflated tire. How is this accomplished in TIREMAAX PRO?

The new tire hose also has check valves at the hubcap end. However, these apply only for the new CP Integrated system. They are held open for PRO to allow air flow during both inflation and relief.

The PRO hubcap uses wheel valves designed to isolate damaged tires or other leaks after the hubcap port. The wheel valve will close should the tire pressure drop below a designed value and the tire hose check valve will close when the tire hose is removed at the hubcap.

4. When TIREMAAX PRO relieves pressure, what tire pressure does PRO relieve to?

During setup, the relief target pressure is set to 10 psi above the inflation target pressure. For instance, if inflation target pressure is set to 90 psi, the relief target pressure is set to 100 psi. TIREMAAX PRO will replenish a drop in pressure below 90 psi and will exhaust excess pressure above 100 psi.

5. Can TIREMAAX PRO be used with both oil and grease hubs?

YES. The only difference is the hubcap window: oil is clear with oil level indication, while the grease is opaque; (not a solid color, but darkened).

6. Will the hubcaps be sold via Hendrickson distribution only and not by the manufacturer?

YES. The hubcap is patented component design and integral part of Hendrickson's new TIREMAAX CP Integrated and PRO systems.

7. Does Hendrickson have a recommended stocking list for TIREMAAX PRO components?

A recommended stocking list for TIREMAAX PRO is available in L1000.

8. How long will the current rotary union be available?

Once the new hubcaps are in production, the current rotary union will not be available for any new suspensions. They will continue to be available for AFTERMARKET service replacements and warranty applications.

9. What is my warranty on TIREMAAX® PRO compared to CP? What will the warranty be for the PRO system? Can I order PRO with an extended service wheel end package like HLS?

All Hendrickson TIREMAAX products have the same warranty coverage currently defined in L583 Comprehensive Warranty Statement and differ for each READY-TO-ROLL® wheel end as listed in the coverage table. Please refer to L583 for more details.

10. How do I justify the cost?

TIREMAAX typically pays for itself in two years or less. Potential savings stems from extended tire life due to less wear, reduced labor expense to check/fill tires, better fuel mileage and reduced road calls.

Also refer to question 11.

11. Is there a comparative cost saving table end user can follow up to achieve benefits of TIS? Does Hendrickson have an ROI calculator for TIREMAAX PRO?

TIREMAAX PRO is the first TIS with relief capability. Some data has been collected during testing, but practical data is not yet available to accurately determine cost savings. However, according to TMC RP 219 Radial Tire Wear Conditions and Causes, many causes of tire wear are attributed to over or under inflation and “mismatched duals for size and/or inflation pressures”.

Also refer to question 10 and 32.

12. What are component costs on TIREMAAX® PRO compared to CP (e.g. hubcap assembly, rotary union and controller)?

For current pricing and availability, please contact Hendrickson OEM or Aftermarket sales team at 866-RIDEAIR (743-3247) or contact your sales representative.

13. How do I specify TIREMAAX PRO for my trailer?

TIREMAAX is available as a factory installed option from most trailer OEMs. In addition, aftermarket retrofit kits can be purchased though standard trailer parts distribution channels for installation on existing vehicles with Hendrickson axles. An ordering guide, L868, is available online at www.hendrickson-intl.com\literature.

Compatibility Questions

14. What are the options for tractor tire positions, if any?

TIREMAAX® is designed to work with fixed axles only and is compatible on any Hendrickson INTRAAX® and VANTRAAX® suspension or Hendrickson TRLAXLE®. TIREMAAX is not available for any tractor tire positions.

15. Can I convert (retrofit) my existing tire inflation system (TIS) to the new TIREMAAX PRO system? Can I convert TIREMAAX CP to TIREMAAX PRO? Are any TIREMAAX CP or EC components compatible with TIREMAAX PRO? Which ones?

OEM provided tubing and fittings can be used, including the Hendrickson manifold and the indicator lamp. The TIREMAAX PRO utilizes the same axle drillings as previous systems, however ALL major system components for TIREMAAX PRO are different.

Also refer to Question 1 and 16.

16. How do the hubcaps from CP and TIREMAAX PRO differ?

Two versions of TIREMAAX CP exist: the original version available prior to March 2012 and the newly designated version (CP Integrated).

For CP available prior to March 2012, all wheel end components are different: e. g. hubcap, rotary union, tee (elbow) fitting, etc. Refer to question 45.

CP Integrated systems purchased during or after March 2012 will utilize the same basic components as PRO, except for the controller and hubcap assemblies. PRO hubcap components are anodized red and the window will display “TIREMAAX PRO”.

Also refer to question 6, and 46.

17. Is there a kit to convert TIREMAAX EC to CP Integrated or PRO? A kit to convert TIREMAAX CP to CP Integrated or PRO?

TIREMAAX PRO will be available in kit form. No conversion kits are planned because of common components between PRO and the original CP/EC systems are very few and primarily consist of hoses and fittings.

NOTE: There are no CP Integrated or PRO hubcaps for earlier HUS (Hendrickson Unitized System) wheel ends available at one time.

Also refer to questions 45 and 16.

18. If I have a rotary union failure, will the new integrated hubcap and rotary union be used in place of the current style?

NO. Unlike the pervious rotary union, which is spindle mounted, the new rotary union is integrated in the hubcap assembly with valves designed to function with the new controller.

19. Can the new rotary union be used on one wheel end without changing both rotary unions on the same axle?

NO - Refer to question 18.

20. Can TIREMAAX® CP Integrated and TIREMAAX PRO be used on TRLAXLE® trailer axles?

21. Can TIREMAAX CP Integrated or TIREMAAX PRO be used on other axles besides Hendrickson? (Meritor, Rockwell) etc.?

Application Questions

22. Do tires still need to be clocked relative to the hubcap when installed?

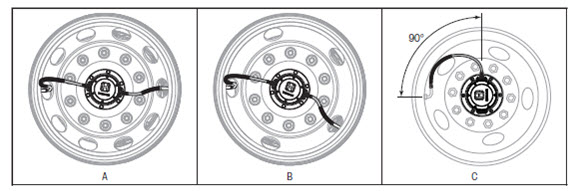

YES - the current TIREMAAX® system, tire hoses are available in a fixed length. Clocking the hubcap contains and controls the tire hose inside the rim area.

23. Is TIREMAAX CP Integrated and PRO tolerant of air system additives?

Whether or not additives are safe to use on any system is dependent on the materials from which the system is made. TIREMAAX valves and seals are made of rubber that has the potential to deteriorate in the pressence of alcohol. The use of air antifreeze with alcohol is not recommended as alcohol will damage rubber seals and valves.

Sealants should not be used with TIREMAAX CP Integrated or PRO because such liquids or powders can back flush into the tire hoses, airlines, components, etc. and cause blockages.

Refer to TMC RP 730 Air Line Antifreeze Recommendations for Trailer Air Brake Systems and RP 235 Guidelines for Tire Inflation Pressure Maintenance.

24. How sensitive are TIREMAAX CP Integrated and PRO to system contaminates (rust, dirt, oil, etc…)?

Other than the presence of alcohol, (reference question 23), most road chemical contaminants will not affect TIREMAAX CP Integrated or PRO performance. Particles entering the system can block ports if too large or a build-up occurs. The Supply Line valve includes a screen which blocks oversized particles from entering the system.

Moisture is always an issue with any compressed air system. The use of an air dryer at the air source is strongly recommended.

25. Can I change my tire pressure setting on the controller out in the field? If so, how do I do it?

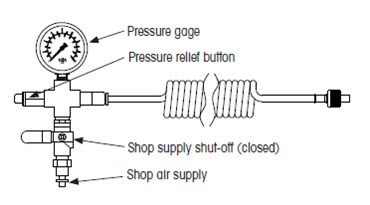

YES. The procedure is outlined T51002. The TIREMAAX® CP Integrated and PRO Calibration Gage is recommended when changing tire pressure settings. Decals must also be updated to reflect the change in target pressures.

26. How far apart do I have to set my target (supply) pressure and (exhaust) pressure? For example, if I set my target pressure at 100 psi, what is my exhaust pressure (105, 110,115)?

Hendrickson strictly requires the relief target be set 10 psi higher than the inflation target. If any other value is used for the relief target, overlapping of target ranges can occur, and the system will not perform properly.

27. What is the recommended procedure to bleed down tires when the air pressure is reset to a lower pressure?

For TIREMAAX CP or TIREMAAX CP Integrated, tires should be manually relieved at the tire hose hubcap end. This same procedure will work with TIREMAAX PRO and is preferred. But, TIREMAAX PRO will automatically relieve the excess pressure during normal operation.

28. What is the maximum and lowest pressure setting available? Is the pressure still specified in 5 psi increments? What is the maximum pressure the system can be set at?

The table below includes specifications for TIREMAAX CP, CP Integrated and PRO pressure settings which are configured in 5 psi increments.

| SPECIFICATION |

US |

METRIC |

| CP tire pressure setting range |

70 to 120 psi |

482 to 827 kPa |

| PRO dual tire pressure setting range |

80 to 120 psi |

552 to 827 kPa |

| PRO wide-based single tire pressure setting range |

90 to 120 psi |

620 to 827 kPa |

For TIREMAAX PRO, the values specified are for the cold tire inflation target pressure. The relief pressure would be set 10 psi higher. In each case, the trailer tank pressure should be maintained at a minimum of 5 psi above the targeted relief pressure.

| |

Example A: |

Example B: |

| Cold tire inflation target= |

90 psi |

120 psi |

| Cold tire relief target = |

100 psi |

130 psi |

| Maintained air tank pressure = |

105 psi |

125 psi |

Note: For above example B, tractor compressor is assumed to max at 125 psi.

29. Will we be offering air pressure adjustment tools for purchase by customers?

YES. The TIREMAAX PRO pressure test gauge is used to set inflation and relief target pressures at the controller. It is designed to fit the test port inside the controller enclosure. The only other tool required is an 1/8 inch hex key. There is also a gauge for CP Integrated. Refer to TIREMAAX Parts List L878.

30. What is the set pressure of the system when not specified?

The TIREMAAX ordering guide includes a mandatory field for specifying the desired cold tire pressure setting. This value is set in the controller at the factory prior to shipping. A decal is included on the front of the enclosure that displays the preset target pressure. The most common pressure settings are 90 and 100 psi.

If the decal is damaged and the cold tire pressure setting is unknown and the controller is assumed to be functioning properly, a good estimate of the target pressure can be obtained by measuring the tire pressure.

31. Why are tire sizes 22.5” and 24.5” listed separately on the TIREMAAX Ordering Guide?

Tire size is used to determine the correct tire hose length for an application, which is the same for 22.5 and 24.5 inch tires. Because these are standard sizes, listing them was simpler than specifying “if greater than” or “if less than” choices.

32. Is there a way to know the best pressure to inflate a tire? As an example, cars have a sticker for the appropriate pressure, but how can we be sure that the customer is selecting the correct pressure for their tires?

Unlike trailers, the distributed load for cars does not change much. But, for a trailer, the load can change from potato chips to batteries. A trailer load of potato chips will max out spatial capacity before maxing trailer weight limits. For batteries, the opposite is likely.

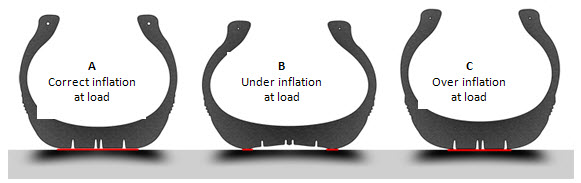

The above image shows road contact cross-sections with changes in pressure and/or load.

Let’s assume “A” is an ideal psi setting with an average trailer load. Condition “B” would then reflect a decrease in pressure or an increase in load while “C” is an example of increased pressure or decreased load. Determining the desired pressure for any given trailer is dependent on many variables outside that of the suspension parameters. At this time, TIREMAAX PRO settings are not intended to be dynamically adjusted.

As stated in TMC RP 235 Guidelines for Tire Inflation Pressure Maintenance (with examples):

“The correct tire air pressure for a vehicle is determined by the loads carried by the individual tires. Using the load and inflation charts in the tire manufacturer’s data book or the Tire and Rim Association’s Yearbook, the load capacity at the required cold pressure for a single tire or for each tire of a dual assembly can be determined.”

Technical Questions

33. How does the system integrate with the tire and trailer air supply?

TIREMAAX uses the trailer supply tank to provide a constant air source to the controller. The TIREMAAX controller continuously monitors the air pressure in the tires and adjusts the tire pressure as necessary to maintain the proper target pressure. The controller is connected to the tires through internal supply lines inside the trailer axle. By using internal supply lines, TIREMAAX hubcaps are non-vented, which reduces the potential for wheel end contamination. These axle lines connect to a rotary union and tire hoses that allow the air to flow to the rotating tires.

34. What are the maintenance requirements of tire inflation systems? How many components are there and what needs to be monitored or replaced periodically?

The maintenance requirements are similar to other trailer air systems, and require periodic inspection for damage and leaks is required. When paired with Hendrickson’s HXL7® extended service wheel end, the TIREMAAX axle components, including the rotary union, are covered by a seven year warranty.

35. How do sensors integrate with the vehicle and air system to know when a tire is properly inflated, and how do they add air when levels fall? (Do they also release air when a tire is over-inflated?)

TIREMAAX PRO is the first automatic inflation system for trailers that can respond to both under-inflated and over-inflated tires. The system features a controller that continuously monitors the tire pressure and automatically fills tires with air from the trailer supply tank anytime the tires fall below a preset level. In addition, with TIREMAAX PRO, if tires become over-inflated due to changes in ambient temperature, the controller will slowly release excess air automatically.

36. How long does it take to install TIREMAAX PRO?

The time required for an installation depends on:

| Operation |

Man-hours |

| Tear-down of existing |

<4 |

| Drilling holes |

<4 |

| Axle hoses and hubcaps |

<4 |

| Controller and testing |

<4 |

| Total |

<16 |

- whether the suspension was specified for TIREMAAX prep

- whether the installation is a retrofit that requires removal of existing components

- the experience of the technician and maintenance shop performing the installation

The table is an estimate of installation time for a tandem axle suspension system. Experienced technicians can reduce the time by as much as a half.

37. Does the TIREMAAX PRO have a blink code fault system like the EC system?

A flow switch in the controller is designed to close at a designated flow rate. Air flow at or above the designated rate turns on the TIREMAAX PRO indicator lamp. There is no digital logic or programming involved.

38. How do I test for leaks in the system?

There are several ways to detect leaks in the system depending on severity and location. Common methods include:

- Visual

- Audible

- Application of leak detector solution or soapy water resulting in visual bubbles.

Refer to Technical Literature T51002 for troubleshooting procedures and information.

NOTE: With TIREMAAX PRO there is no pressure downstream of the controller when the trailer park brakes are set. When looking for leaks, the trailer must be safely immobilized and the park brakes released.

39. How can I diagnose valve/rotary union issues?

40. How do I check tire pressure to ensure the system is working properly? If the process is automated, is the driver alerted as well?

The first step to ensuring a properly functioning system is observing the indicator lamp located within view of the driver. It will illuminate to show air flow in the system.

The procedure for manually checking tire pressures is done at the tire hose, similar to the previous TIREMAAX EC and CP systems, as defined in the manual (T51002).

41. With today’s tire inflation systems, I have to periodically check my tire pressure. Will I still have to perform these checks with the TIREMAAX PRO system?

Tire inflation is a critical function of trailer operation. Tires should be checked according to manufacturer guidelines. The TIREMAAX PRO system will maintain a + or – 5 psi difference to the targeted psi set on the controller. The TIREMAAX indicator lamp will illuminate while air is flowing to inflate tires or compensate for leaks. Any suspicion of a problem should be investigated. Guidelines for interpreting the indicator lamp status are available in T51002 TIREMAAX CP Integrated and PRO installation, service and troubleshooting manual.

42. Can an air pressure gauge be installed on the delivery side of the control box to see what my air pressure is at all times?

TIREMAAX PRO does not provide any delivery pressure at the controller whenever parking brakes are set.

43. If I lose a TIREMAAX PRO tire hose, can I use a CP tire hose? Are TIREMAAX CP hoses compatible with the TIREMAAX PRO system?

NO. Among other differences, the tire hose from the previous EC/CP systems are female thread at the hubcap fitting, while tire hoses for the new CP Integrated / PRO are male threads. TIREMAAX PRO and TIREMAAX CP Integrated do not use the same tire hoses.

44. Can the TIREMAAX PRO system be shut off? How?

YES. A disconnect procedure is defined in T51002 glove box card and on the decal affixed to the cover of the controller. To do so, set the trailer parking brake, then close supply line valve at on the left side of the controller and remove tire hoses.

45. Since so many parts are incorporated into the hubcap, can it be repaired rather than just replaced? What components of the TIREMAAX® CP Integrated and TIREMAAX PRO hubcap are serviceable?

NO. The intricate hubcap components are assembled in a controlled environment. The same conditions are not guaranteed in the field.

Also refer to question 16.

46. Is there a way to check the hubcap for proper functionality without installing it (bench test)?

Hubcaps are bench tested after assembly at the factory. The troubleshooting section of T51002 identifies some issues that may occur relative to the hubcap and recommends replacing it ONLY. At this time, there is no field test for hubcaps, other than swapping them between wheel ends to see if the symptoms move.

47. What components on the TIREMAAX CP Integrated or TIREMAAX PRO controller are serviceable?

The controller enclosure includes integrated components that are not serviceable. Should a controller problem exist, replacing of the entire controller is required. However, the troubleshooting section of literature T51002 does point out that escaping air is normal at the controller under certain circumstances.

MISCELLANEOUS

48. What information is contained in T51002 TIREMAAX CP Integrated and PRO installation, service and troubleshooting?

A. An overview of how the system works.

B. Complete installation procedures for all Hendrickson axle types.

C. How to change inflation and relief target pressures.

D. How to test the system.